OUR SERVICES

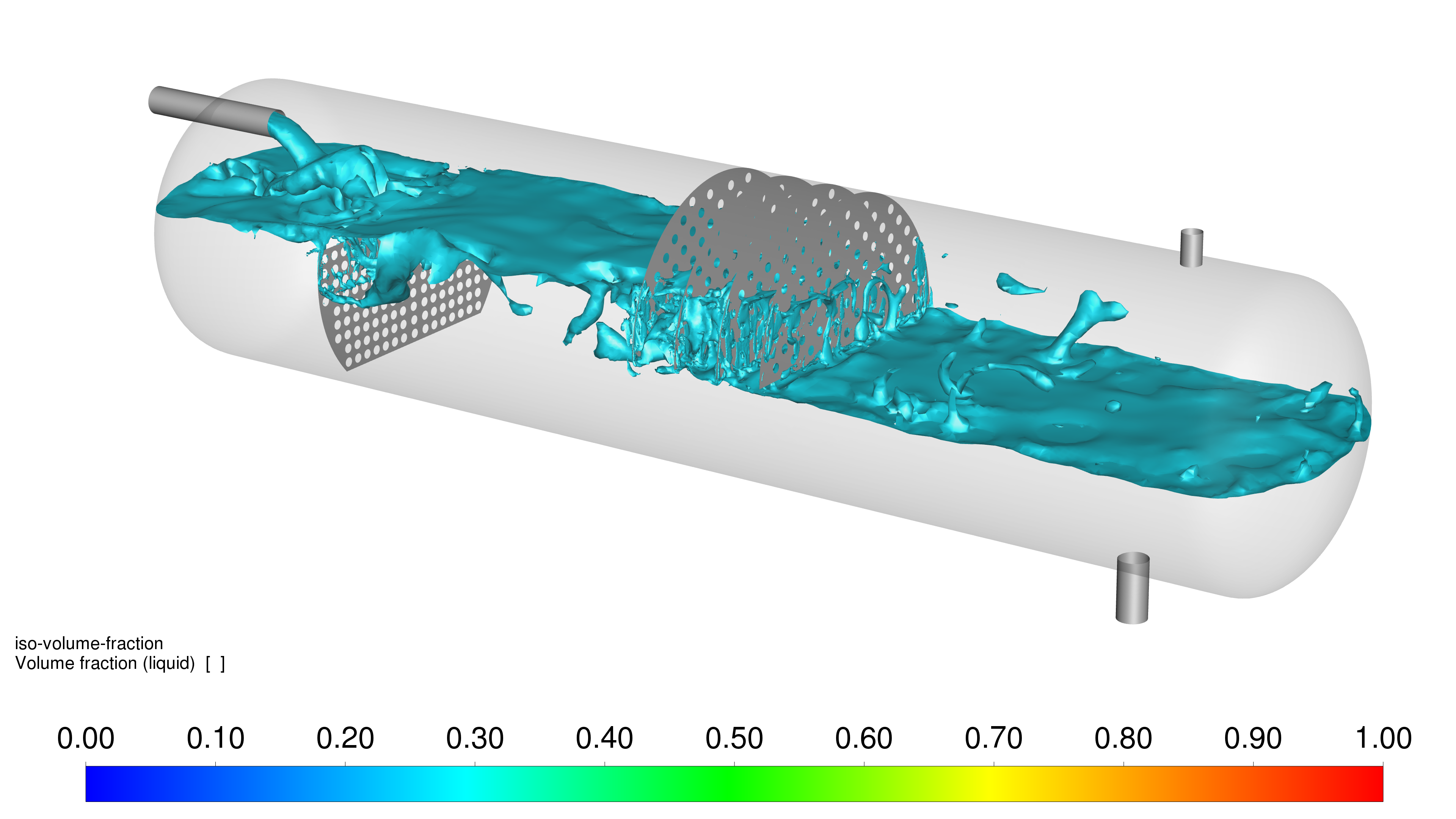

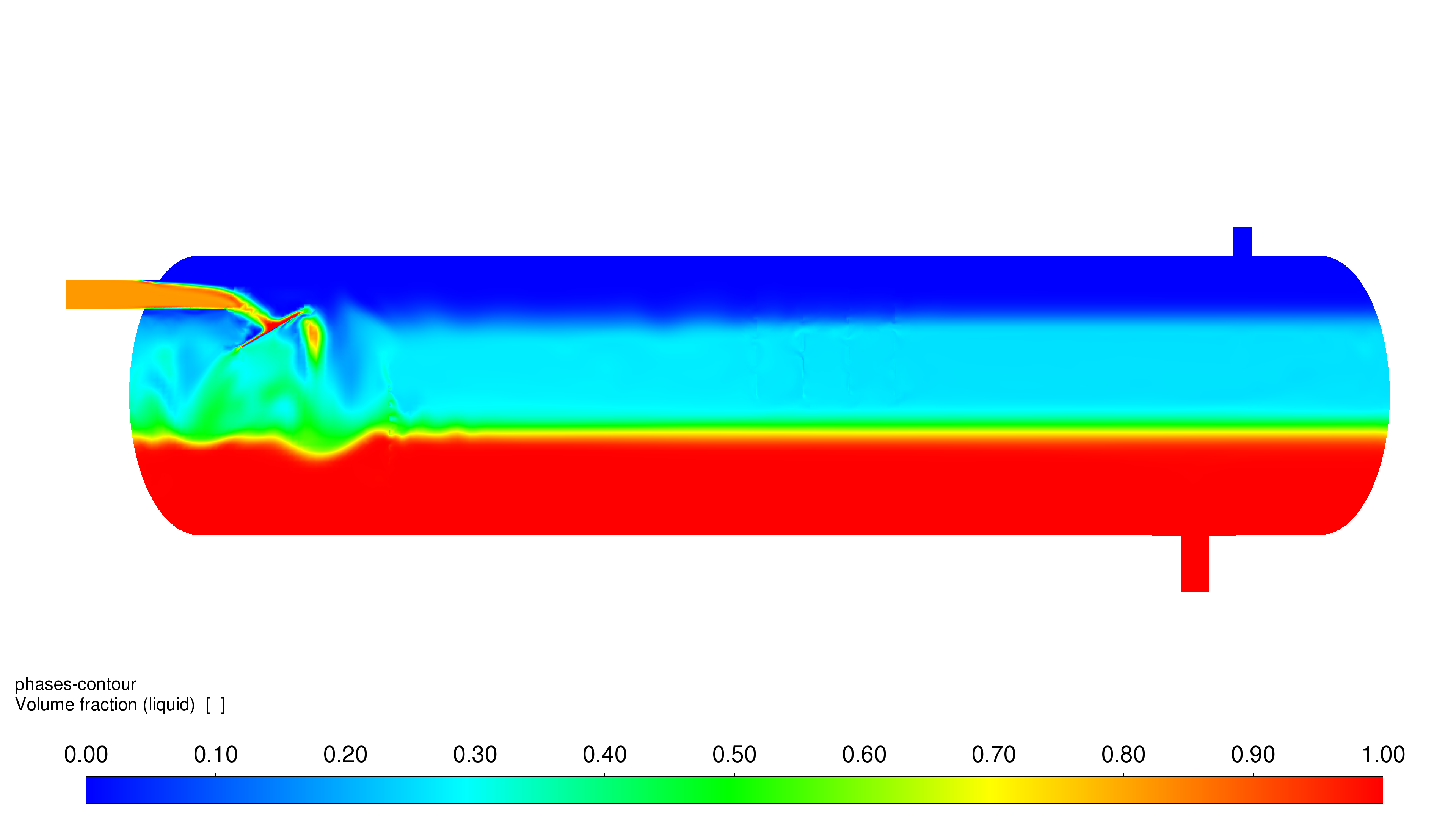

Numerical Simulation CFD and FEA

Computational Fluid Dynamics (CFD) and Finite Elements Analysis (FEA) are branches of fluid mechanics that utilizes numerical methods and algorithms to solve and analyze problems involving fluid flow. It’s widely used in various industries, including aerospace, automotive, energy, environmental engineering, and biomedical engineering, among others.

CFD allows engineers and researchers to simulate and analyze fluid flow phenomena, such as turbulence, heat transfer, and chemical reactions, within complex geometries and under various operating conditions. This technology is particularly valuable in situations where experimental testing is expensive, time-consuming, or impossible due to extreme conditions.

CFD simulations can be used for a wide range of applications, including:

- Design optimization of aerodynamic components in aerospace and automotive industries.

- Predicting fluid flow patterns and heat transfer in HVAC systems, buildings, and industrial processes.

- Analyzing pollutant dispersion in the atmosphere and water bodies for environmental studies.

Overall, CFD plays a crucial role in engineering design, analysis, and optimization, enabling engineers to make informed decisions and improve the performance of fluid systems and processes.

Automation and SCADA Solutions

Automationrefers to the use of technology to control machines and processes with minimal human intervention. This can range from simple tasks like turning on a light switch to complex industrial processes such as refining oil or manufacturing cars.

SCADA (Supervisory Control and Data Acquisition) systems are used to monitor and control these automated processes. They collect data from sensors and other devices, present it to human operators on a central interface, and allow them to adjust the process as needed. SCADA systems are often used in conjunction with Programmable Logic Controllers (PLCs), specialized computers that can control industrial machinery.

SCADA systems are used in a wide variety of industries, including:

- Manufacturing

- Oil and gas

- Water and wastewater treatment

- Power generation

- Chemical processing

- Food and beverage production

Energy Management Systems

Energy Management Systems are critical in helping organizations manage energy resources, reduce operational costs, and achieve sustainability objectives by optimizing energy consumption and improving energy efficiency across their facilities and operations.

- Monitors: An EMS gathers data on energy consumption from various sources like meters, sensors, and utility bills. This provides a comprehensive view of energy usage patterns.

- Analyzes: The EMS analyzes the collected data to identify areas of high consumption, potential inefficiencies, and opportunities for savings.

- Optimizes: Based on the analysis, the EMS suggests or implements actions to reduce energy use. This might involve adjusting equipment settings, scheduling operations during off-peak hours, or recommending energy-efficient upgrades.

Benefits of EMS:

- Cost Savings: EMS can significantly reduce energy consumption and cost by identifying and addressing inefficiencies.

- Sustainability: Lower energy use translates to reduced greenhouse gas emissions, contributing to environmental sustainability.

- Improved Efficiency: EMS helps optimize energy use, leading to smoother operations and potentially increased productivity.

- Informed Decisions: Data-driven insights from the EMS can guide informed decisions regarding equipment upgrades, energy procurement strategies, and overall energy policies.