study cases

DECANTER

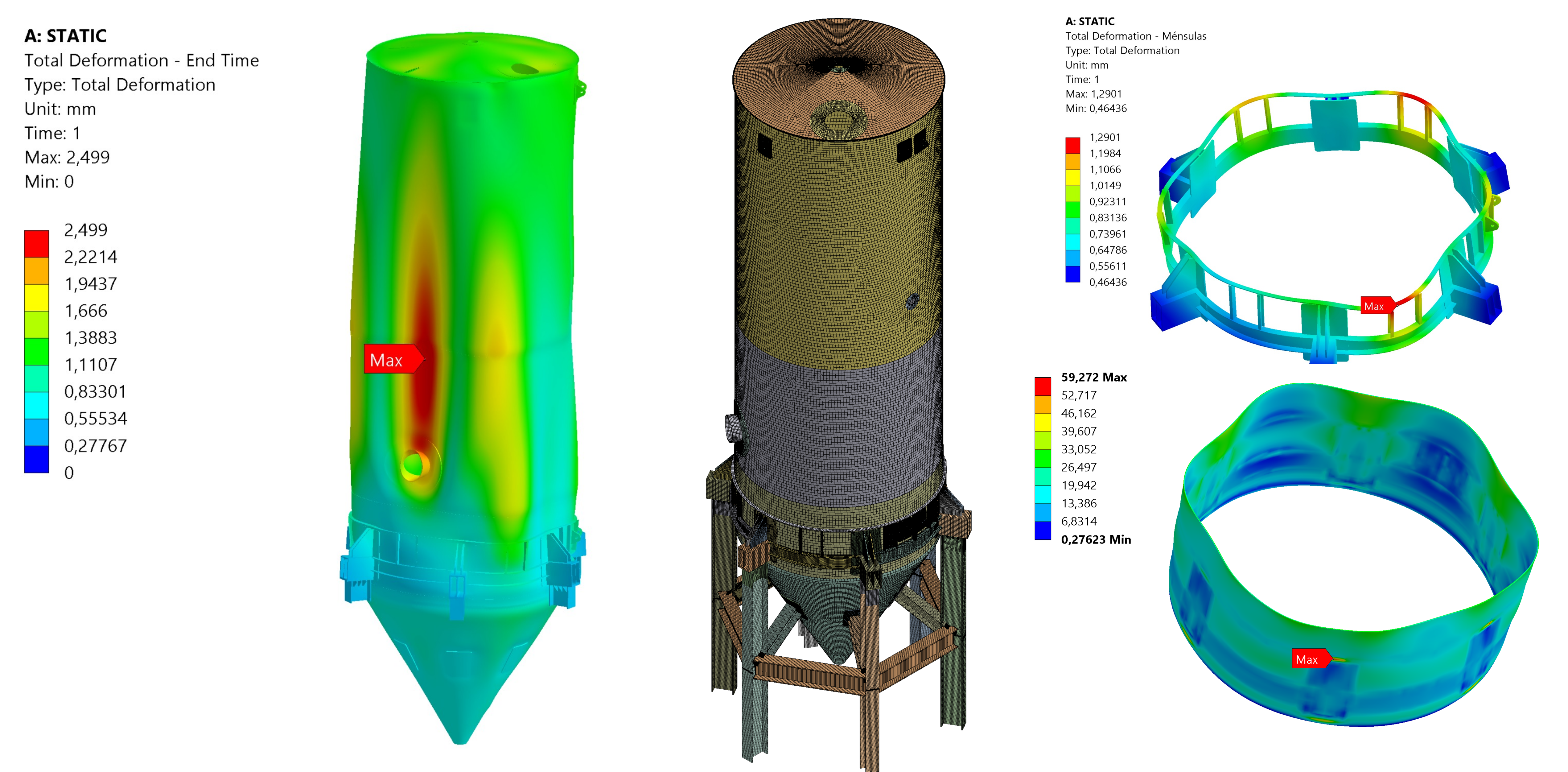

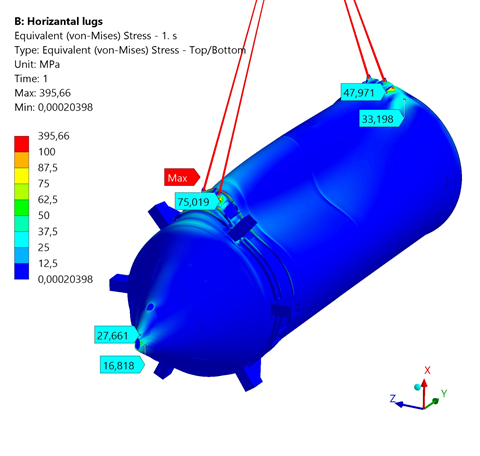

Stress and Strain analysis of Mechanical Equipment

The mechanical integrity of complex machinery can be evaluated in various situations. Analytical equations are often incapable of performing this task. Numerical methods like the finite element method can be used to test and analyze equipment in circumstances such as regular operation, seismic loads, lifting, and erection. These methods help identify sections of the equipment that experience stress concentration. By doing so, critical areas can be reinforced to ensure structural integrity while keeping the cost reasonable.

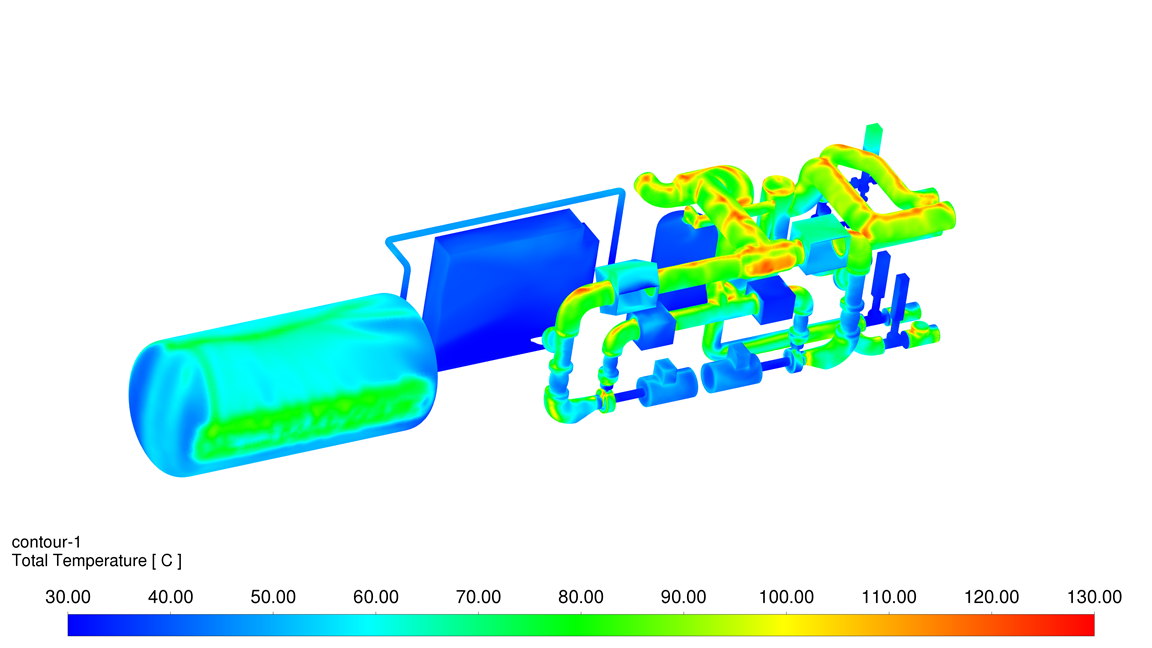

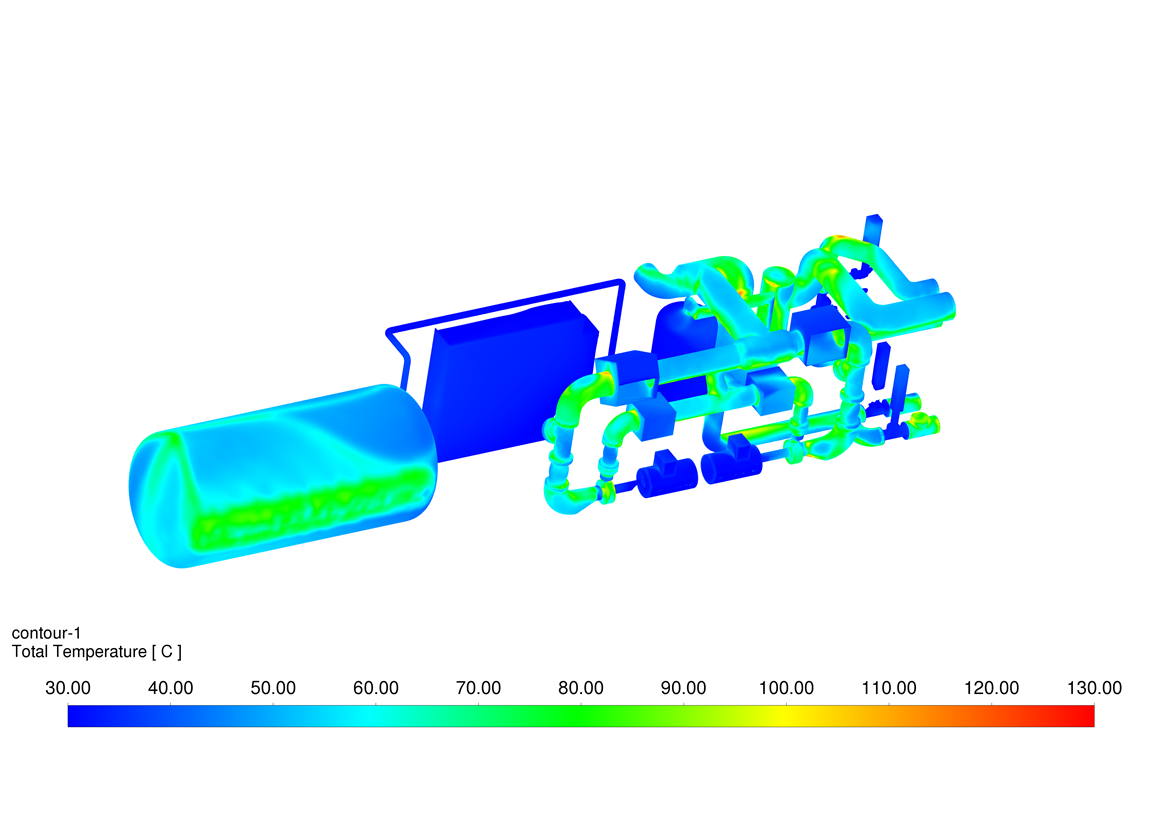

HVAC

HVAC and Heat Transfer Analysis

CFD solvers can be coupled with the energy equation. Hence, it is possible to analyse fluid flow problems with heat transport. The client built a sheltered skid for a thermal oil pumping system in the present example. There was an overheating problem with the pump motors and the control panel within the container due to the small room size and poor cooling. A CFD simulation was conducted to diagnose the problem and solve this issue. Later, a solution consisting of an extractor fan and a diffuser were strategically located to ensure the pump motors’ cooling, avoiding reducing the temperature at the pipes’ surface as they transport hot oil to different processes in the plant.

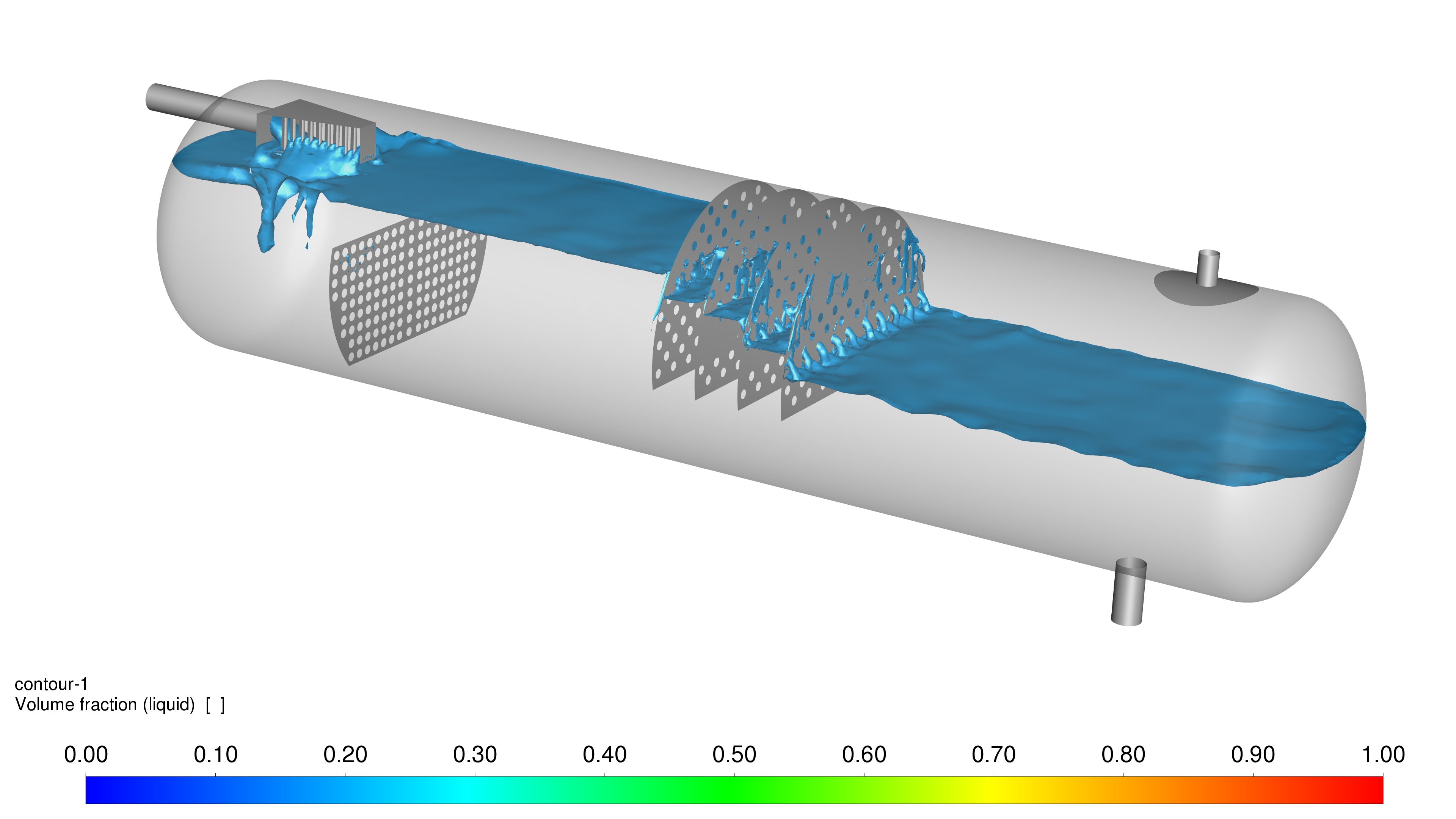

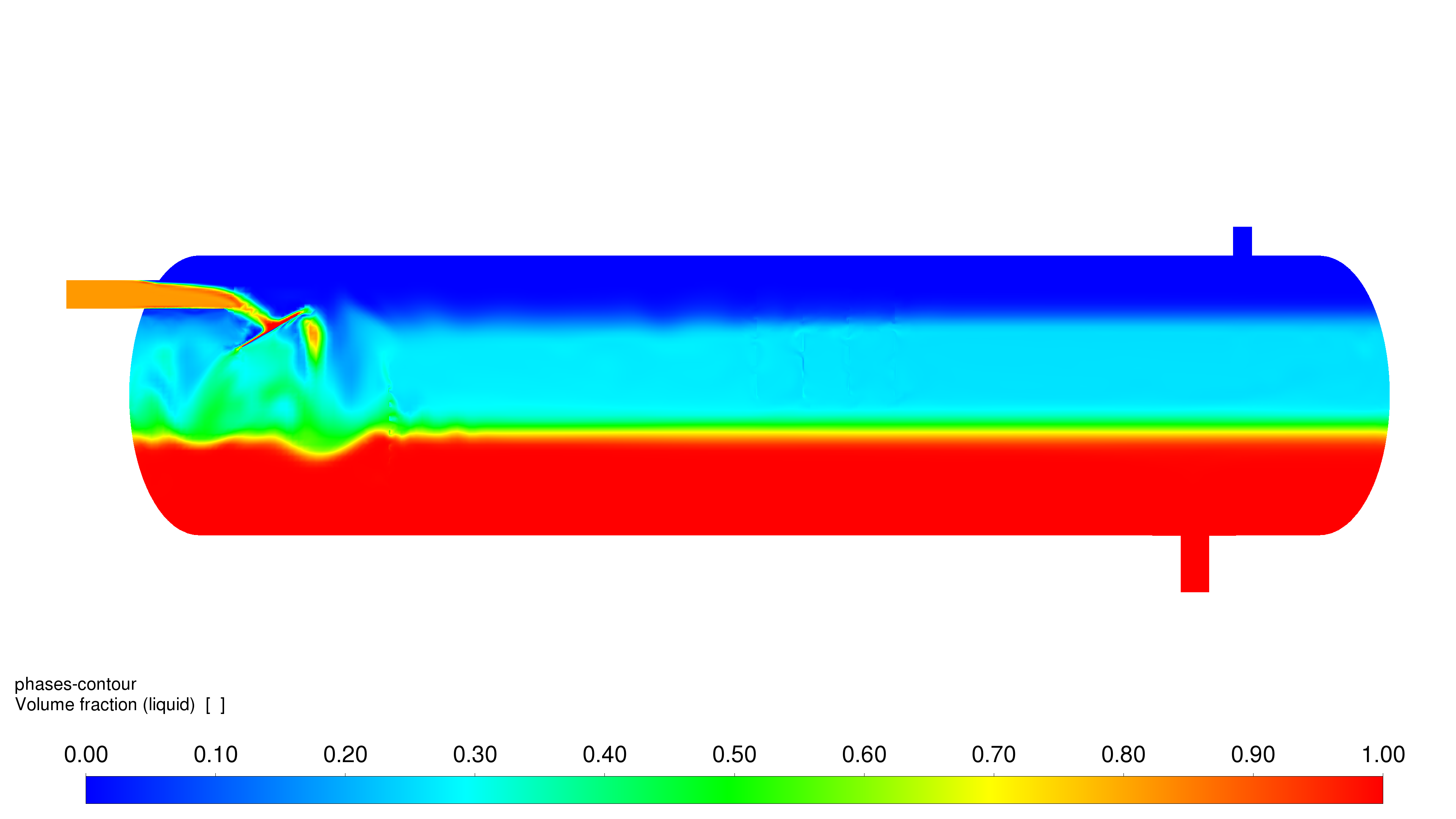

SEPARATION EQUIPMENT

Design of internals to improve the performance of separation equipment

We are capable of conducting numerical simulations to test and design the best internal parts of two or three-phase separators to achieve a high separation efficiency within the equipment. In the present example, different types of inlet flow diverters and several arrays of baffles were numerically tested to remove dispersed liquid droplets from the gaseous phase and promote the coalescence of liquid particles. As a result, the gas phase was dehydrated to continue towards the following process.

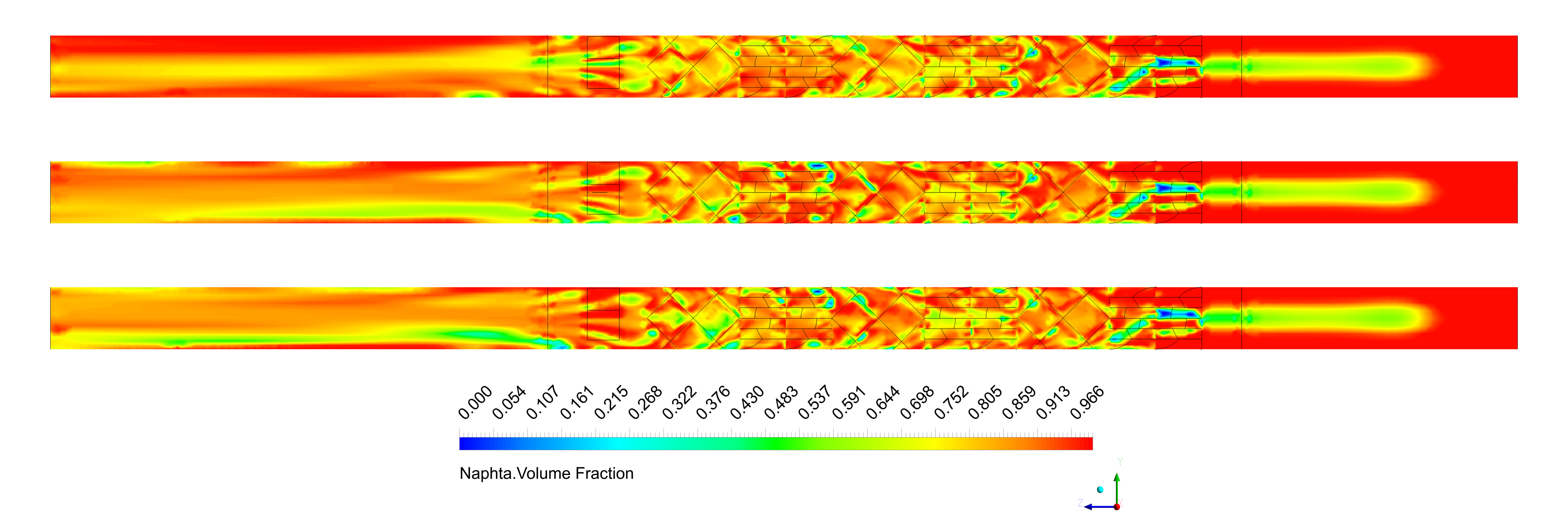

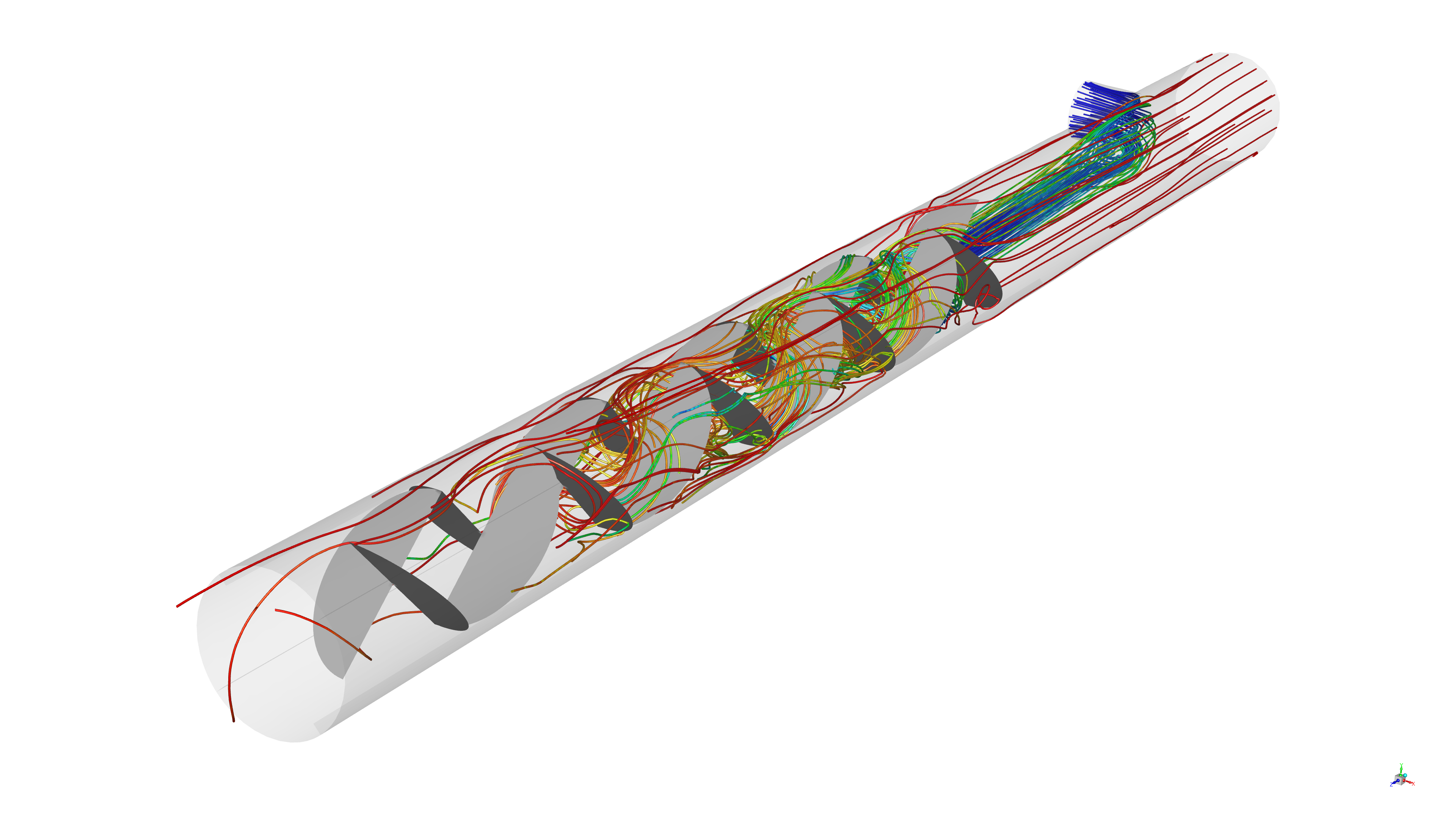

MIXING TECHNOLOGIES

Sized and designed several equipment for mixing purposes

Using computational fluid dynamics (CFD), we have sized and designed several equipment for mixing purposes. In this example, several configurations for a static mixer were numerically evaluated to obtain a suitable mixture of Nafta with a caustic soda solution. A configuration SMX with six mixing stages was the final design and the best choice to properly mix the components with total pressure drop .